Unlocking improved food texture and taste

Making plant-based products more juicy, nutritious and popular

If you’ve ever been disappointed by a dry, stodgy veggie burger, you’ll know that not all plant-based products are created equally.

Now researchers at Leeds have developed a groundbreaking new technique that can make alternative proteins more juicy, improving textures as well as having the desired nutrition and sustainability.

14.5 per cent? 11? Almost 20? It’s difficult to know just how much of the world’s greenhouse gas emissions are the result of livestock production. Regardless of the figures debated by experts, it’s doubtless a significant problem for a planet facing climate catastrophe.

Reducing our dependency on animal-derived foods is therefore a core ambition for governments and groups wishing to cut carbon outputs. In fact, if we could use alternative sources for half of the world’s protein and dairy consumption, emissions would stop rising and actually decline by 31 per cent by 2050.

But currently, such ambitions seem, well, ambitious.

Sales of meat alternatives have been in sharp decline, falling by as much as 13.6 per cent in 2023 as many plant-based brands struggled to meet forecasts and some companies even slipped into administration.

Analysts have chalked up the trend to the cost of living crisis, with meat-free products often more expensive than their traditional counterparts, and an overcrowded marketplace that grew too much, too quickly.

But whisper it quietly: there’s also another reason why shoppers are shunning veggie burgers and vegan hot dogs.

And it’s one that lower inflation alone can’t address.

The trouble with texture

“It pains me to say it,” Professor Anwesha Sarkar from the University of Leeds said, “but to be honest, most of the plant-based foods on the shelves simply don’t taste nice; they’re dry and have a really astringent mouthfeel.”

Taste and texture, of course, are hugely subjective topics. But Anwesha, who grew up in India eating her fair share of vegetarian and vegan food, isn’t just expressing her personal opinion.

As Chair in Colloids and Surfaces in the School of Food Science and Nutrition, Professor Sarkar heads up several projects including the Innovate UK-funded SusProFood, investigating the whys and wherefores of plant-based texture and flavour with partners in industry.

“There’s been a race to develop products without all that much science going into the food, which has really affected quality,” Anwesha, who has extensive experience in texture research and has invented several patents, explained.

“If we want to change that, we’ve got to understand the problems and work out the scientific causes and factors behind consumer comments like ‘it tastes dry’ or ‘it’s too chewy’.”

To that end, Anwesha and her colleagues developed a quantification that, together with anecdotal descriptions from tasters, could be used in sensory rating tests to judge the mouthfeel quality of specific alternative proteins.

By defining attributes like ‘slippery’ (as “the ease in which the sample slides through the mouth during chewing and slips away from the tongue”) and ‘dry’ or ‘astringent’ (as “the frictional force between the tongue and the palate caused by food residues”, the researchers could make far better use of human feedback.

And in general, such negative opinions are not surprising to Anwesha.

“Plant proteins are storage proteins; they serve to store nutrients for the plant, so they’re very aggregated and insoluble in water – which often presents itself as a sort of grittiness,” she said.

But when she arranged for more than 20 of her colleagues and students to conduct a taste test with around 50 plant-based commercial products from supermarket shelves, Professor Sarkar didn’t expect the level of feedback it generated.

Dr. Ben Kew preparing food for the session

Dr. Ben Kew preparing food for the session

Students working with Anwesha get hands-on to evaluate the mouthfeel of plant-based products – tasting led by Dr. Ben Kew, postdoctoral fellow

Students working with Anwesha get hands-on to evaluate the mouthfeel of plant-based products.

Addressing the flaws

I was so disappointed, out of all those items, there were only a handful that were what I’d even call palatable.

At present, food manufacturers often enhance the flavour or texture of their products by adding ingredients like salt or fat.

To Anwesha, this is akin to painting over the cracks, and even introduces other barriers to take-up, too.

“Without doing something really scientifically thought through to plant proteins, they’re never going to hold water and will stay dry and astringent no matter what you add in,” she said. “That also stays true no matter how many additives you add, which consumers consider unhealthy and a reason to buy meat instead.

So it was obvious that there was a definite need for more cutting-edge solutions that could make alternative proteins more appealing.

Textures, theories and an artificial tongue

Thanks to funding from the European Research Council, Professor Sarkar and colleagues embarked on a mission to do exactly that.

In partnership with SPG Innovations and the drinks brand Innocent, the team at Leeds is now set to work firstly with a view to drawing objective measurements of texture in real food applications.

“We use in vitro tools to analyse the proteins so we can effectively convert comments like ‘dry’ into quantifiable concepts like friction and lubricity,” Anwesha said. “We’re taking advantage of physical chemistry to understand what each ingredient is doing so that hopefully the minimum amount of additional processing is used later on.”

This stage is so crucial that Anwesha and interdisciplinary scientists at Leeds have even 3D printed a tongue-like synthetic surface in an impressive world first.

It wasn’t easy to accurately map the human tongue and replicate that with a material that’s similar in elasticity, but it is a huge boon to our research.

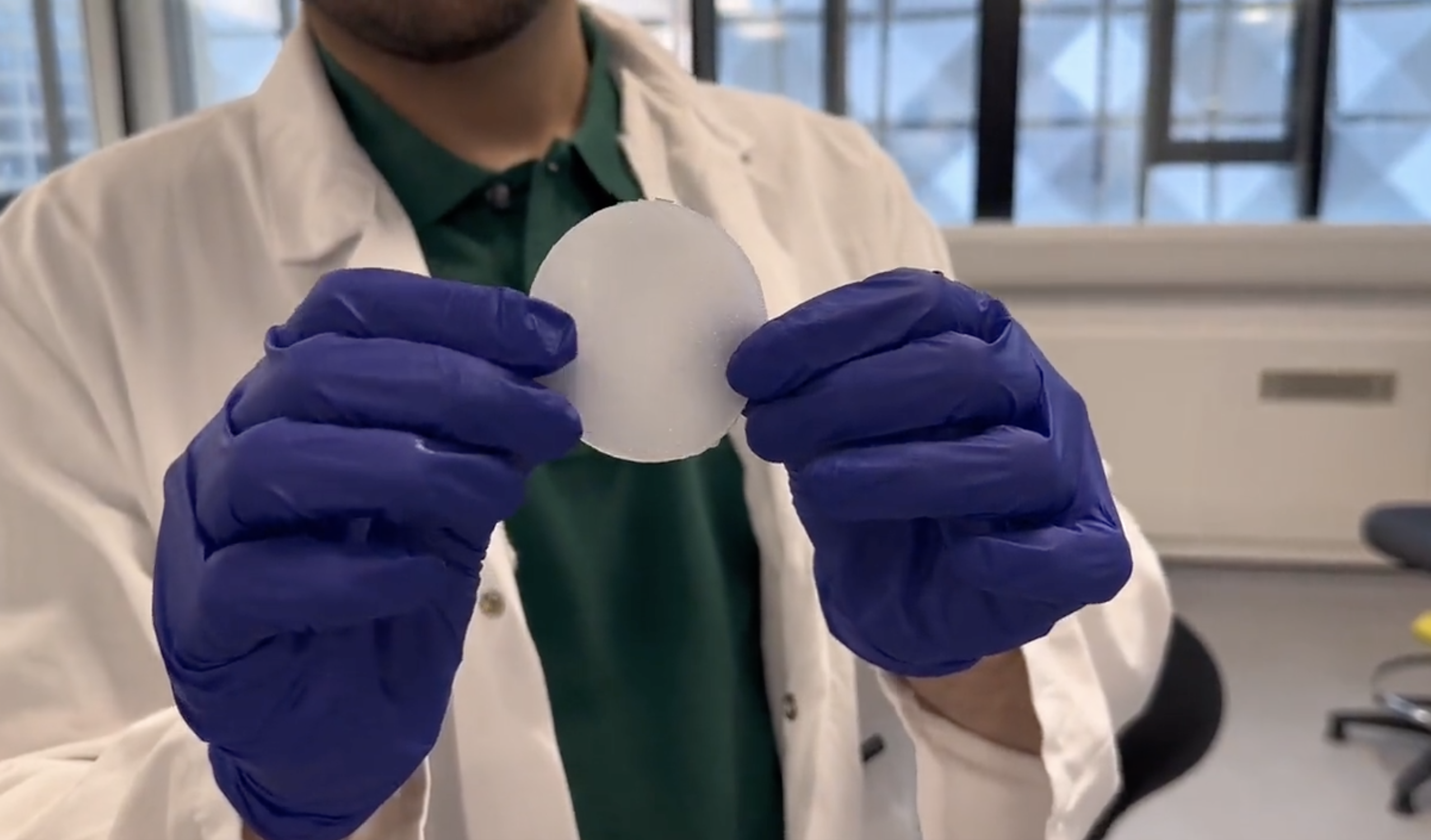

The biomimetic tongue with the new polymer used by the team.

The biomimetic tongue with the new polymer used by the team.

Making the first ever 3D biomimetic tongue involved running a series of experiments using different complex fluids, which ensured the surface behaved in the same way as the real thing when coming into contact with liquids.

The tool will also aid research in oral care and therapeutic technologies – but for Anwesha, it’s already proved invaluable in her work.

It’s helping us work out exactly what characteristics people like in food and why. For instance, there’s a perception that the more fat you put in chocolate, the tastier it will be.

“By contrast, what we’ve found is that it’s only that initial bite that seems to matter; so we can instead think of it as a gradient, concentrating a higher percentage of fat at the surface layer and then have dramatically less on the inside, making a healthier product while maintaining enjoyment.

“It wasn’t easy to accurately map the human tongue and replicate that with a material that’s similar in elasticity, but it is a huge boon to our research.”

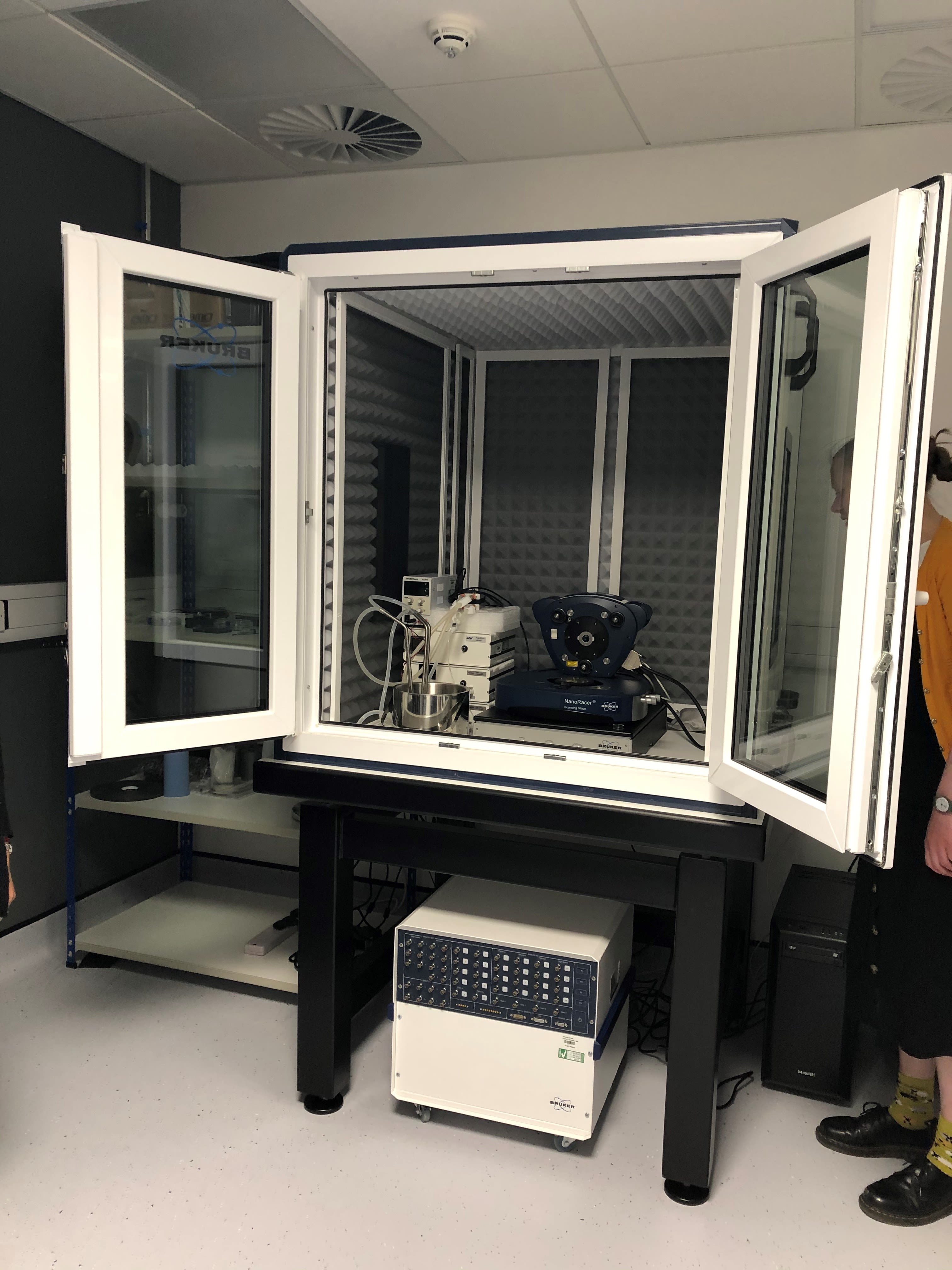

An atomic force microscope used at Leeds to observe biological processes as they happen at 50 frames per second.

An atomic force microscope used at Leeds to observe biological processes as they happen at 50 frames per second.

Small-scale solutions for big problems

But let’s get back to alternative proteins.

Just how exactly can we solve the dryness problem to make plant-based ‘meat’ that provides a better feel in the mouth?

Although Professor Sarkar and colleagues had a good idea, confirmation that they were on the right track came thanks to the advanced scientific equipment available elsewhere within the University.

“We had a theoretical belief that a process called microgelation would be able to transform plant proteins from a gloopy and dry state into a juicy, fat-like one,” Anwesha said.

“Essentially, you place the proteins in water and heat them up, which alters the physics of proteins.”

This method forms a 3D gel that traps water around the plant protein and is then homogenised, breaking the protein network into a microgel of tiny particles too small for the naked eye to see.In order to test the hypothesis, the team used the atomic force microscopy suite in the Faculty of Engineering and Physical Sciences.

“It was an exciting moment that proved the concept,” Professor Sarkar said.

“The protein microgels were pretty spherical and were not clumping together, and the result is that when they’re under pressure while being eaten, they ooze water and create a lubricity similar to that of single cream – without using a single drop of oil.”

Microgelation, then, adds much-needed hydration and juiciness to the feeling of eating plant proteins – and the only key ingredient is water.

“It doesn’t need any chemicals. It doesn’t need any added agents. It’s just water and a technique that’s widely available and already used in the food industry,” Anwesha noted.

Shaping tomorrow’s menus

The breakthrough opens the door for manufacturers to take an eco-friendly approach to making their plant-based products more appetising, while at the same time stripping them of the added salt, sugar and saturated fats they may have added previously as a workaround for mouthfeel enhancement.

Anwesha sees huge potential for the new method at what is a particularly exciting time in her field.

“I’ve worked in India, New Zealand, Switzerland and the UK, and what I’ve seen everywhere is a growing buzz around the issue of planetary health,” she said.

“Now, with our biomimetic tongue, we can do far more efficient in vitro testing that allows us to quickly experiment with different formulations before going to sensory trials.”

It makes it possible to improve recipes in a faster, cheaper way, because we can narrow things down to the versions with the best texture before they are then tried by people for real.

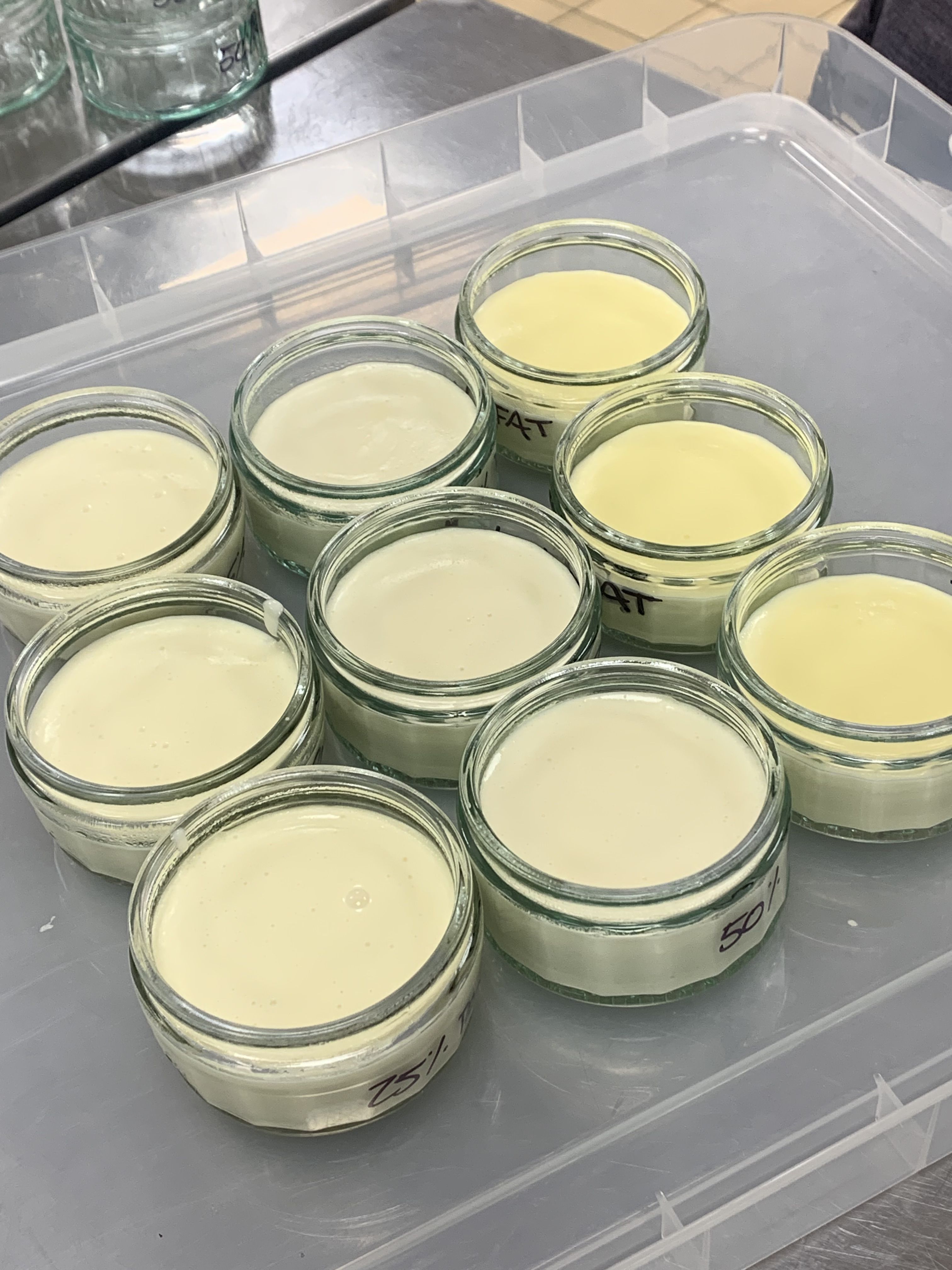

A panacotta-like product made with the microgel.

A panacotta-like product made with the microgel.

Professor Sarkar believes that helping manufacturers create alternative proteins that are more enjoyable to eat could breathe new life into a stagnating market. “Food is an emotional thing; it’s not just about filling your belly. We remember eating tasty meals and it isn’t enough to make healthier, more sustainable foods if they won’t create those moments,” she said.

Our research is demonstrating that nature is amazing and there’s no need to add other things.

By understanding the physical chemistry of proteins across length scales and working with them in a different way instead of covering them in less nutritious ingredients, we can make something mouthwatering – which is exactly what we need to do if we want a healthier, greener planet.

Experts

Professor Anwesha Sarkar

Anwesha is Chair in Colloids and Surfaces at the School of Food Science and Nutrition.

She joined the University of Leeds in 2014, having previously worked at the Nestlé Global Research Centre in Lausanne and Nestlé headquarters in Vevey.

Anwesha’s research interests lie at the crossroads of experimental colloid science and human health, with themes including oral processing and tribology, microstructure, and edible nutrient delivery systems.

Dr Ben Kew

Ben is a Post-doc fellow researcher in plant protein, sensory and product application.

He is researching oral-tribology, rheology and nano-scale adsorption of food protein emphasising on alternative plant/insect proteins. Working in-lab and in sensory testing this research aims to be applied in ultra-lubricating fat mimetics and predictive mouthfeel capabilities in the formulation of healthier, more consumable sustainable alternative protein foods.